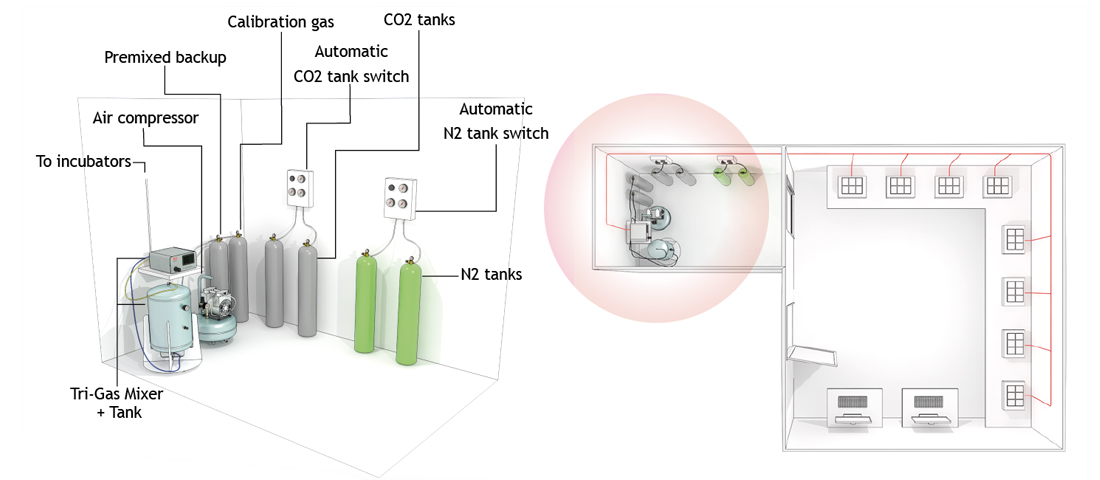

The Tri-Gas Mixer is a digital CO2-O2 controller that mixes CO2, Air and N2 to the desired concentration ranging between 0-10% for both CO2 and O2, and at controlled pressure in the range of 0-2 barg (0-30 psig).

Delivery pressure is easily regulated by adjusting the knob of the embedded pressure gauge. The device is equipped with a mixing tank to ensure the highest composition stability even when the required output flow is variable.

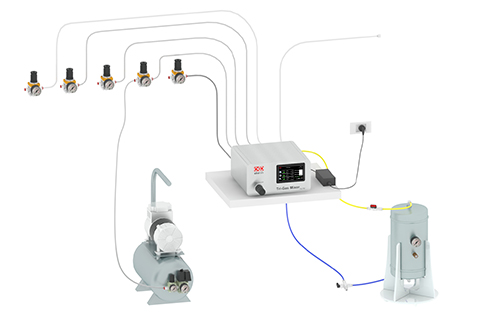

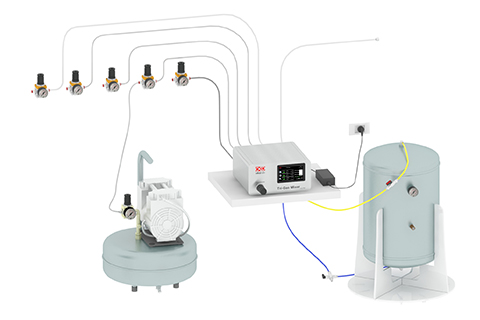

The Tri-Gas Mixer is compatible with any mini incubator available on the market.

The Tri-Gas Mixer is equipped with a CO2-O2-MODULE, which contains the CO2 and O2 sensors.

The CO2-O2-MODULE measures with a high accuracy the CO2-O2 volume concentrations allowing automatic fine-tuning of the output gas. The CO2-O2-MODULE is factory calibrated using certified gas cylinders, and the factory calibration certificate is included in electronic format.

The CO2-O2-MODULE can be conveniently calibrated on-site with intuitive routines or can be easily extracted from the Tri-Gas Mixer, replaced with a spare CO2-O2-MODULE and sent out for calibration.

In both cases, there is no need to disconnect or turn off the Tri-gas Mixer not to discontinue the gas supply to the incubators.

The Tri-Gas Mixer features the self calibration procedure to periodically calibrate the CO2 and O2 sensors, by using a connected calibration gas with a gas concentration close to the concentration used during the standard working condition.

The self calibration procedure is automatically and periodically repeated to maintain high accuracy for your operations. Moreover, the self calibration procedure can be manually started with an intuitive procedure.

The Tri-Gas Mixer always sends the proper gas to the connected incubators, even during the self calibration procedure.

The Tri-Gas Mixer is compatible with any bench-top incubator available on the market. Models are available with maximum output flow rate of 1.5 L/min and 15 L/min. The actual flow rate delivered automatically adjusts to match the requirements of the connected equipment.

Technical Specifications

| Output maximum flow rate | Air Compressor | Mixing tank size | |||||

|---|---|---|---|---|---|---|---|

| TRI-GAS MIXER 1.5 LPM | 1.5 L/min | AIR-COMPRESSOR-1.5L | 4L | ||||

|

|||||||

The Tri-Gas Mixer features advanced safety routines to ensure that the incubators always receive the proper gas.

To enable the safety routines the Tri-Gas Mixer must also be connected to a premixed backup cylinder containing gas of the desidered concentration.

The mixer will automatically switch to the premixed backup gas if any of the following conditions occurs:

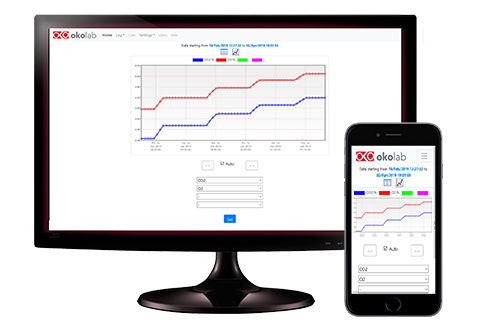

The Tri-Gas mixer features wireless and ethernet connections. The remote data viewer allows:

Android and IOS mobile app will be avaiable soon.

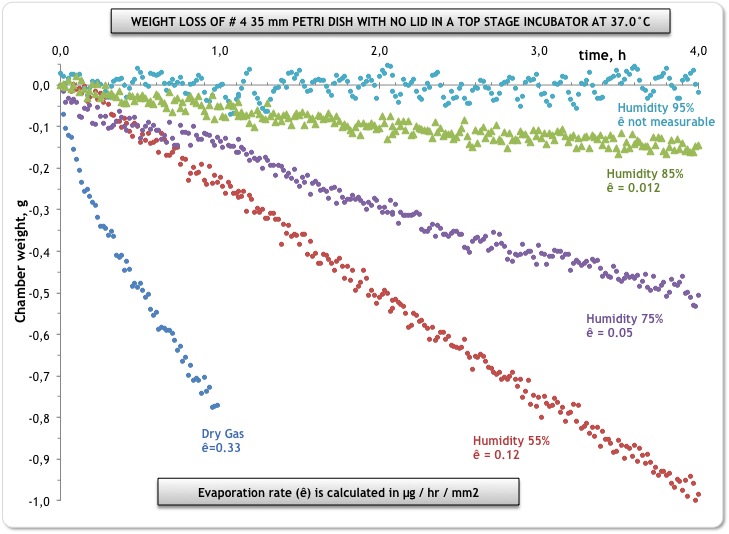

HM-ACTIVE controls the Relative Humidity inside the chamber in the range 50-95% with a resolution of 1%.

The dry gas is humidified by flowing over warm water. The Humidity sensor regulates water temperature in order to achieve the desired relative humidity in the chamber.To prevent water condensation, the tube connecting the humidity controller to the chamber is heated.

COPYRIGHT © OKOLAB S.R.L. ALL RIGHT RESERVED. CERTIFIED ISO 9001.